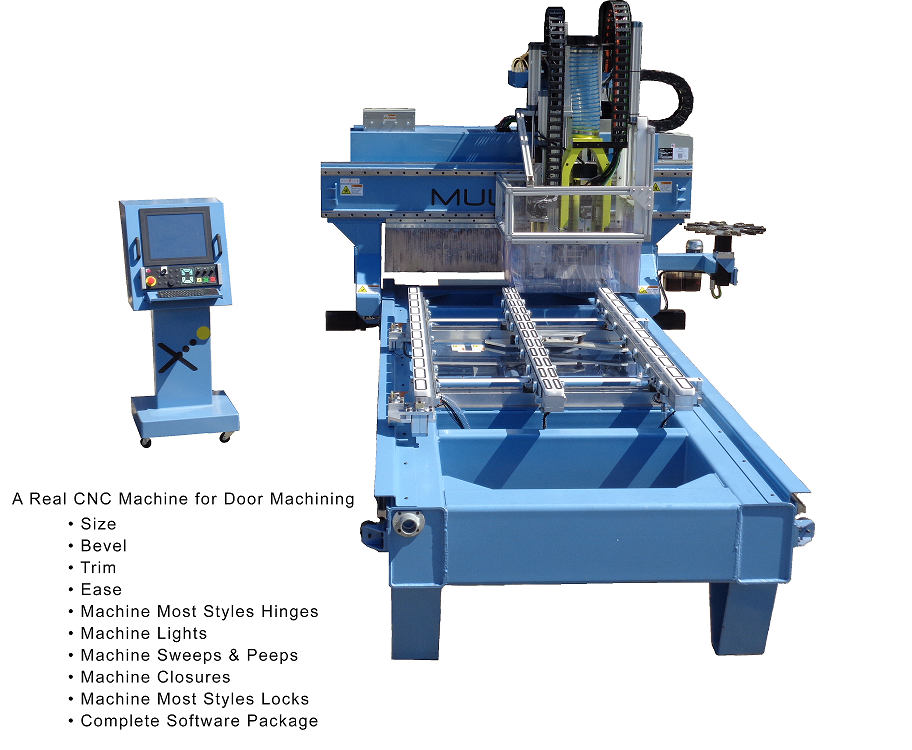

Multiax NE Machine

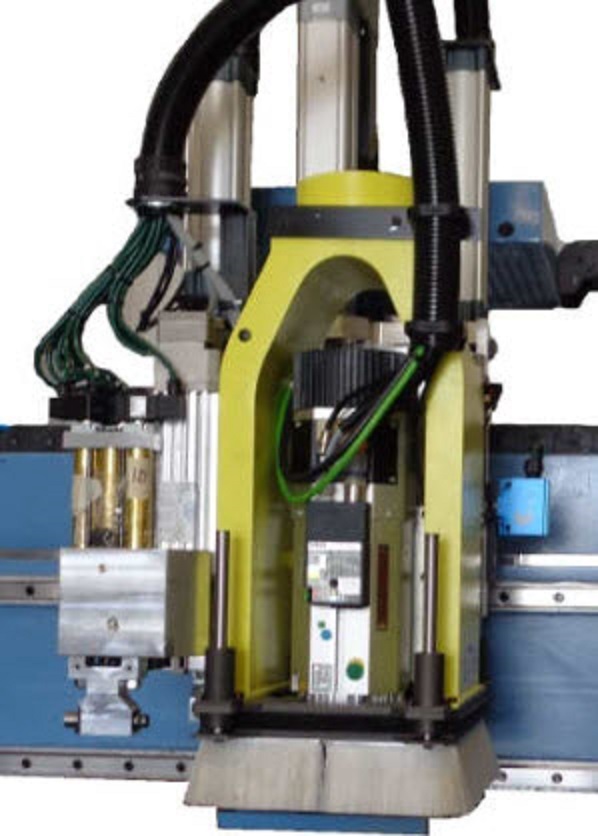

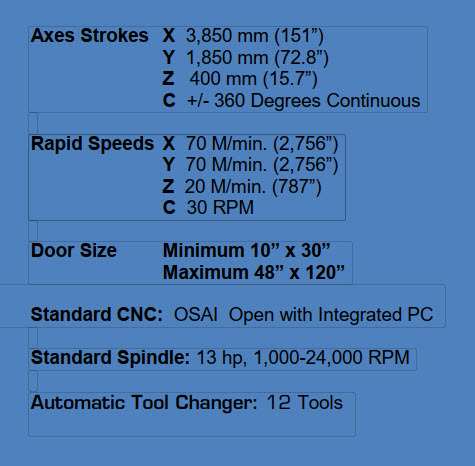

The Multiax NE machine is a moving bridge machine designed with the door distributor in mind. A feed through design that allows for easy loading and unloading. The CNC controlled fixture has pop up rollers and removable vacuum pods. The machine has a 4 axis spindle allowing full machining of doors including: sizing, beveling, trimming, easing, machining most styles of hinges and locks, lights, sweeps & peeps, and closures. Underneath machining within 6” of the edge can be completed without flipping the door. A complete 3D perimeter software package allows for programing from a system of drop down menus and libraries of different hardware with little to no programing experience required.

Special Door Fixture Includes:

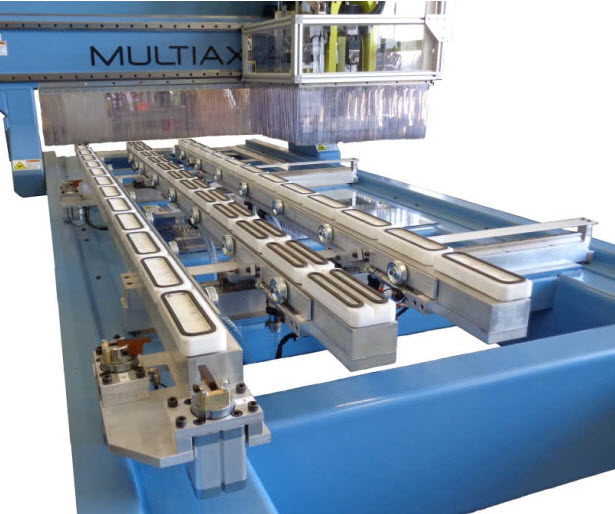

• CNC Controlled Fixture Positioning to Adjust to the Door Width.

• Reference Stops Designed to Handle Overhanging Laminates.

• Pop Up Rollers for Easy Loading and Unloading.

• Removable Vacuum Pods When Performing Through Cutting.

• Center Rail Designed for Splitting Doors.

• Fixture Designed to Machine Up To a 48” x 120” Door.

• Able to Size, Bevel, Trim, and Machine Hinges, Lights, Sweeps,

Peeps, Closures, All Styles Locks, ETC.