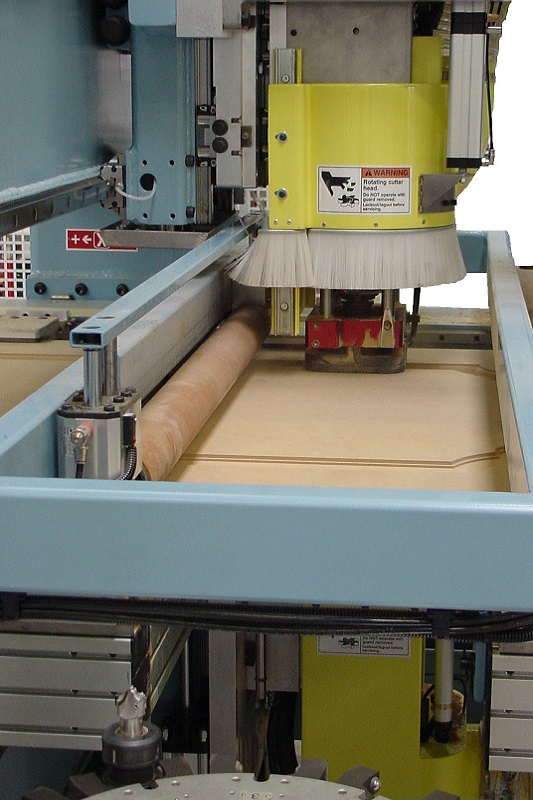

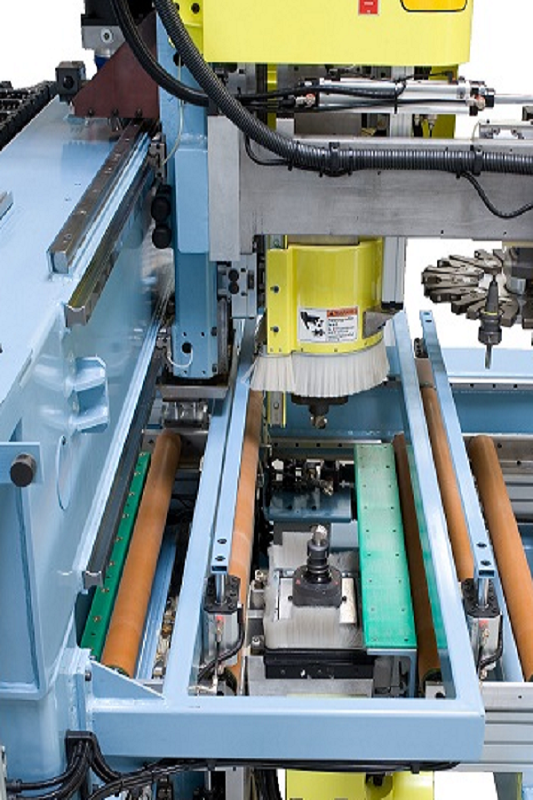

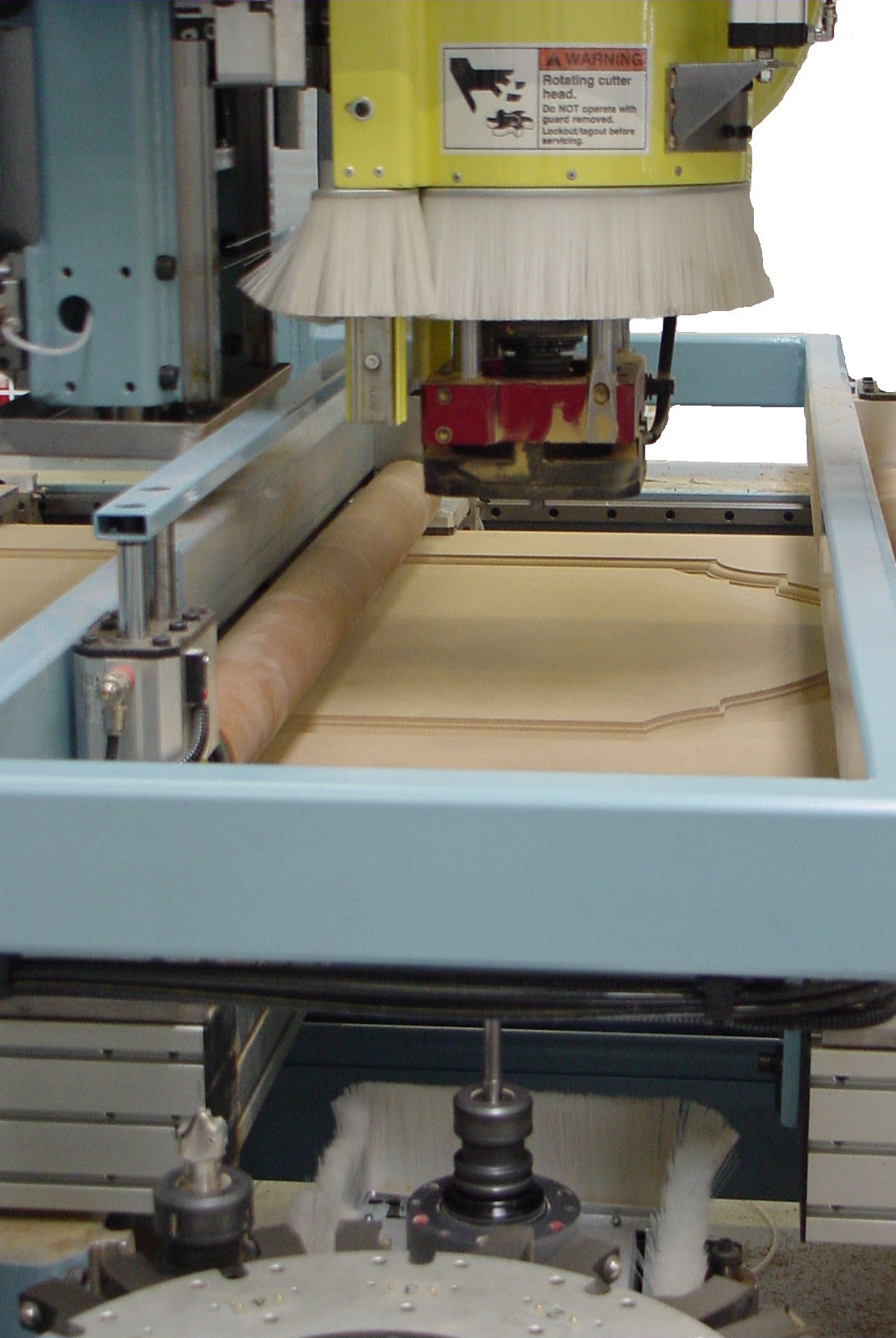

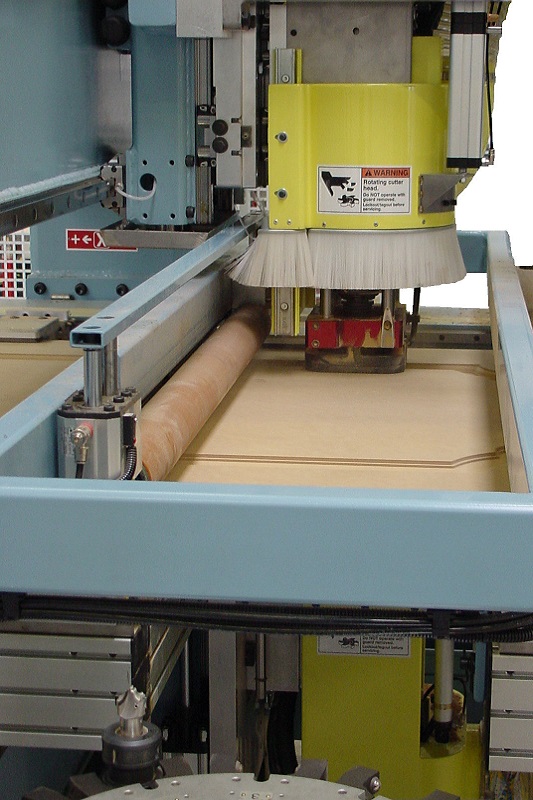

Multiax D Machine

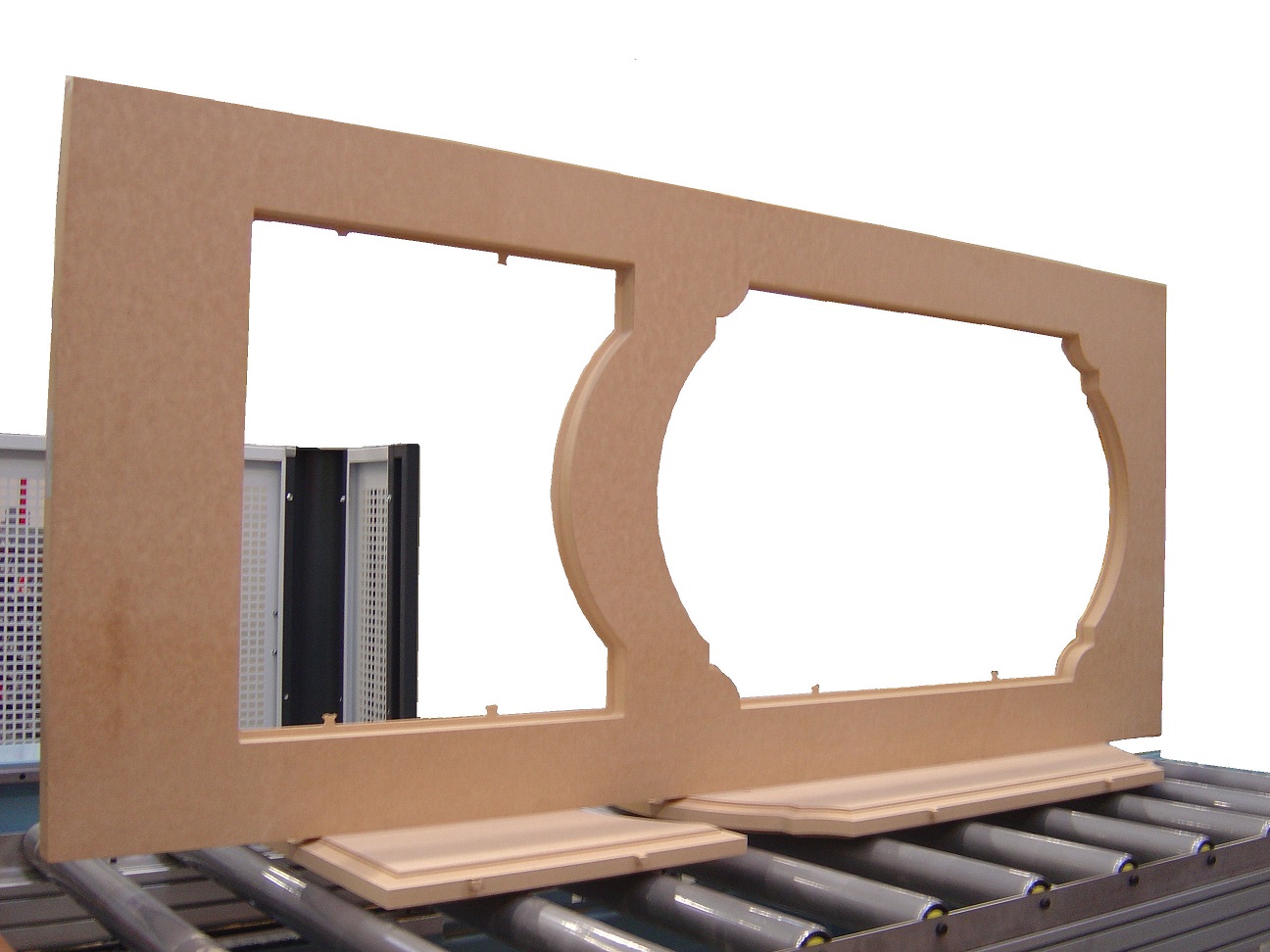

The Multiax D Machine is a rugged, compact, fixed bridge structure, feed thru machine with 3, 4, or 5 axis movements in a single or multi-spindle design. It is a simultaneous top AND bottom machining center. It has been engineered to perform face machining, face profile machining, door core machining and sizing, light cutouts, etc. It’s rugged construction leads to High Accuracy and unprecedented “up-time”. The machine can be configured with one, or two machining heads for the top and bottom cutting. It can be fitted with automatic load and unload for high productivity and efficiency.

MDF Door Machined on the

Top and Bottom Machine