C DOOR MACHINE

C Door Series

Feed Through Door Machine

The Multiax CNC Door Machining System is a productive, accurate and very flexible machining system with the ability to perform the following tasks:

- Simultaneous machining of up to three processes, two hinges and one lock

- Fully automatic in feed, door positioning and out feeding.

- Size doors from 10” x 40” up to 4’ x 10’

- Machine doors that are already sized.

- Perform 3 degree edge beveling

- Perform most all types of hinge

- Perform most all sweep & closer machining.

- Perform most all cylinder lock, mortise lock, dead bolt, etc,

- Square chiseling for face plates.

- Underneath routing in order to eliminate door flipping.

- Machining of door lights and peep

- Misc face and edge machining.

- Complete surface machining of MDF doors.

- Cutting speeds up to 2000” per minute

- Bar code reading and complete material handling is available

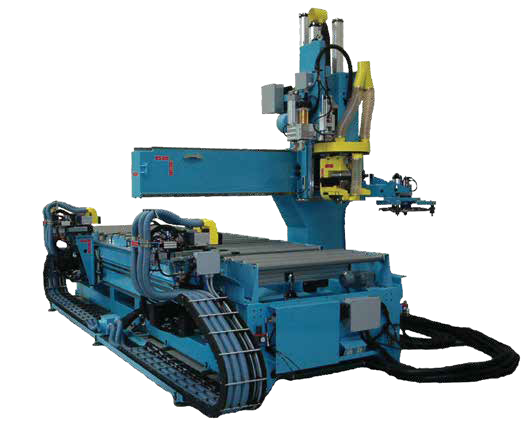

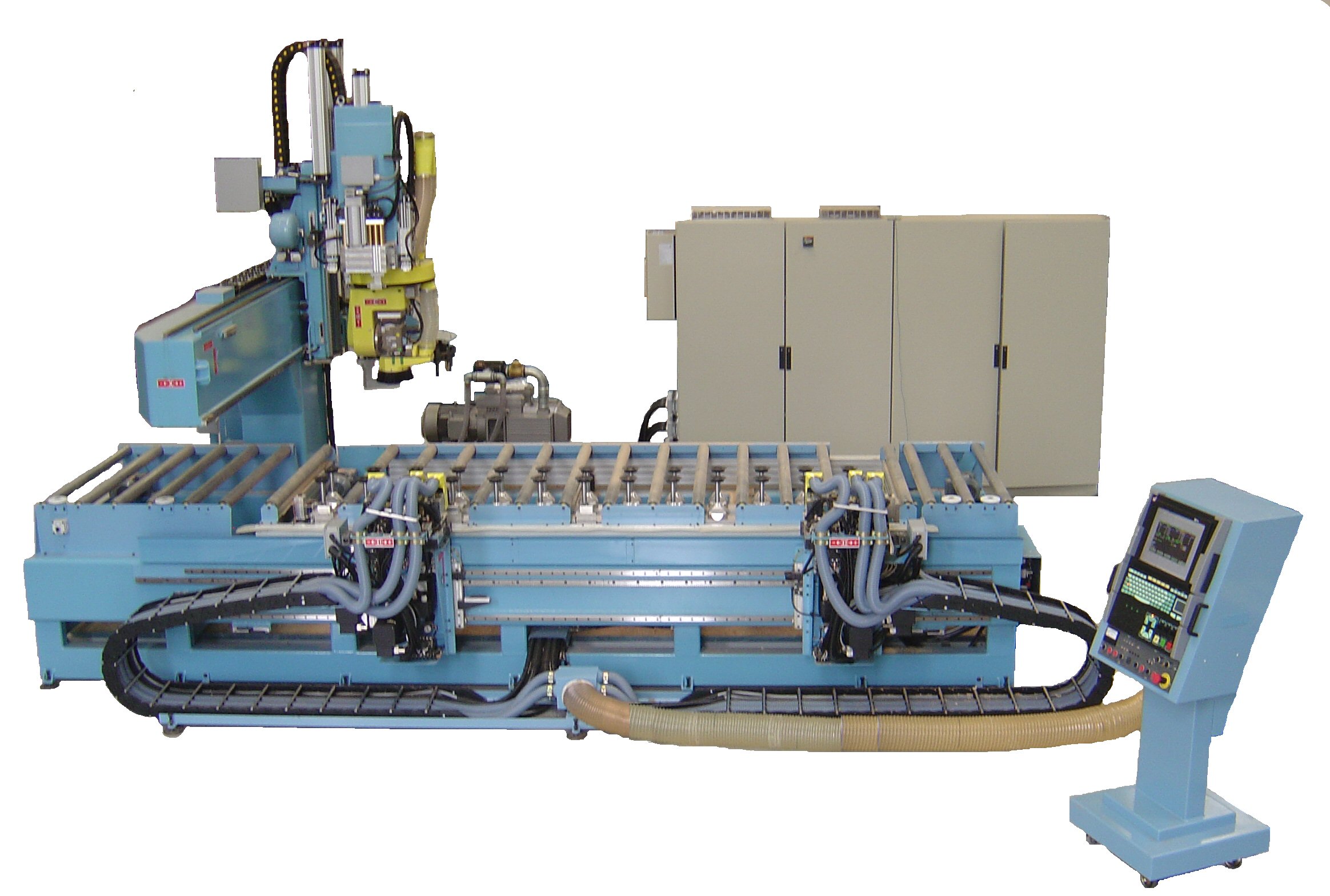

Automatic in feed and out feed system, this system adjusts for the width and length of the door and the hardware machining required.

Three independent working units, the two front units machine for hinges, simultaneously as the main unit machines for the lock set.

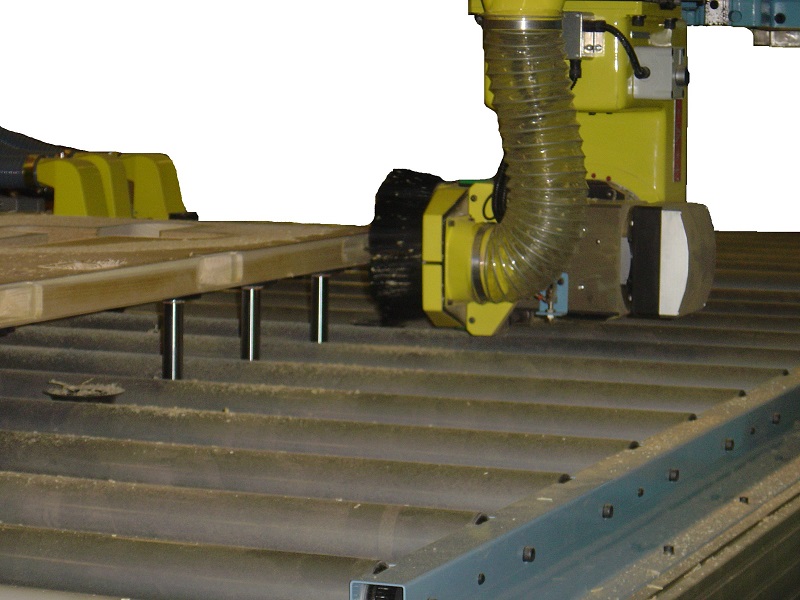

Each door hinge unit has two router spindles, (one right hand rotation and one left hand rotation) one drill spindle and one square chisel with the ability to work at zero, plus three, or minus three degrees. Complete with integrated dust extraction.

The machine is equipped with an aggregate unit, for machining underneath the door. Ideal for lock hardware that requires different patterns on the bottom surface of the door.

The main 5 Axes spindle can pick from 16 tools on the tool magazine. The tool magazine can store router bits, saw blades, aggregates, etc. The tool magazine travels with the bridge of the machine.

Reference stops rise up and rotate, locating using the stile and rail, not an overhanging surface laminate.

MODEL

C 1111 – 3713

Main Bridge Stroke-Rapid Traverse

X/3,800 mm (149.6”) – 60 meters/min (2,362”)

X/1,500 mm (59.05”) – 50 meters/min (1,968”)

Z/600 mm (23.62”) – 20 meters/min (787”)

Rotational Axis

A Axis +/- 120 degrees – 30 RPM

C Axis +/-270 degrees – 30 RPM

Horizontal Units

X1 & X2/ 3,800 mm (149.6”) – 40 meters/min (2,362”)

Y1 & Y2/ 112.5 mm (4.429”) – 20 meters/min (787”)

Z1 & Z2/ 80.5 mm (3.17”) – 20 meters/min (787”)

Table Size

One 3700 x 1300 mm

Table Type

Feed through work table equipped with rollers of 60 mm diameter on 230 mm centers. Between the rollers there are two lines (the first is fixed) of vacuum pods with a vertical movement of 110 mm to raise the door off the rollers and clamp it to the machine bed. The position of the second line of vacuum pods is controlled by the CNC and it can hold pieces from 250 (9.84”) to 1.250 mm (48”) in width.

Vacuum Type Pump

2 Pumps, 140 CMH, dry vein type

Heads for Machining

Fitted on moving bridge:

One, 5 axis, 10 Kw, 13 hp, HSK 63, liquid cooled, 1000-24,000 rpm, 4 pole spindle. One, point to point boring unit with 7 vertical and 2 horizontal exits, with 70 mm of Z stroke. Fitted on front side of machine, along the X axis, two independent carriages, with X1 & X2, Y1 & Y2 and Z1 &Z2 movement and +/- 3 degrees, each carriage fitted with:

Two, 2.2 Kw, 3 hp, router spindles, one for right & one for left hand rotation,18,000 rpm. One, 1.5 Kw, 2 hp, drilling spindle, 18,000 rpm.

One pneumatic corner chisel.

Automatic Tool Changer

16 tools each, carousel type, 100 mm. pitch

Standard Equipment

16 tool holders HSK 63 with CCT treatment

16 collets: customer specifies

Inverters

One piece, 11 Kw, from 1,000 to 24,000 rpm, main spindle.

Four pieces, 2.2 Kw, from 1,000 to 18,000 rpm, horizontal routers

Two pieces, 1.5 Kw, from 1,000 to 10,000 rpm, horizontal drills

Three pieces, .55 Kw, for in-feed, out-feed and table rollers

C.N.C. Controller

OSAI Open, including: 12 axis movement, step by step mode, Industrial Panel PC, 17″ VGA

LCD TFT color, HD 20Gb, Ethernet

Operator Panel

Mounted in separate mobile cart

Lubrication

Automatic by oil